New vertical roller mill will for coal refinement Mineral Processing

Vertical roller mill VRM Grinding Cement mill 1. Introduction The Indian cement industry have many major players in the league. The top 20 cement companies produces almost 70% of the total installed production capacity in the country.

Raw Coal Vertical Roller Mill Cement , High Performance Vrm Cement Mill

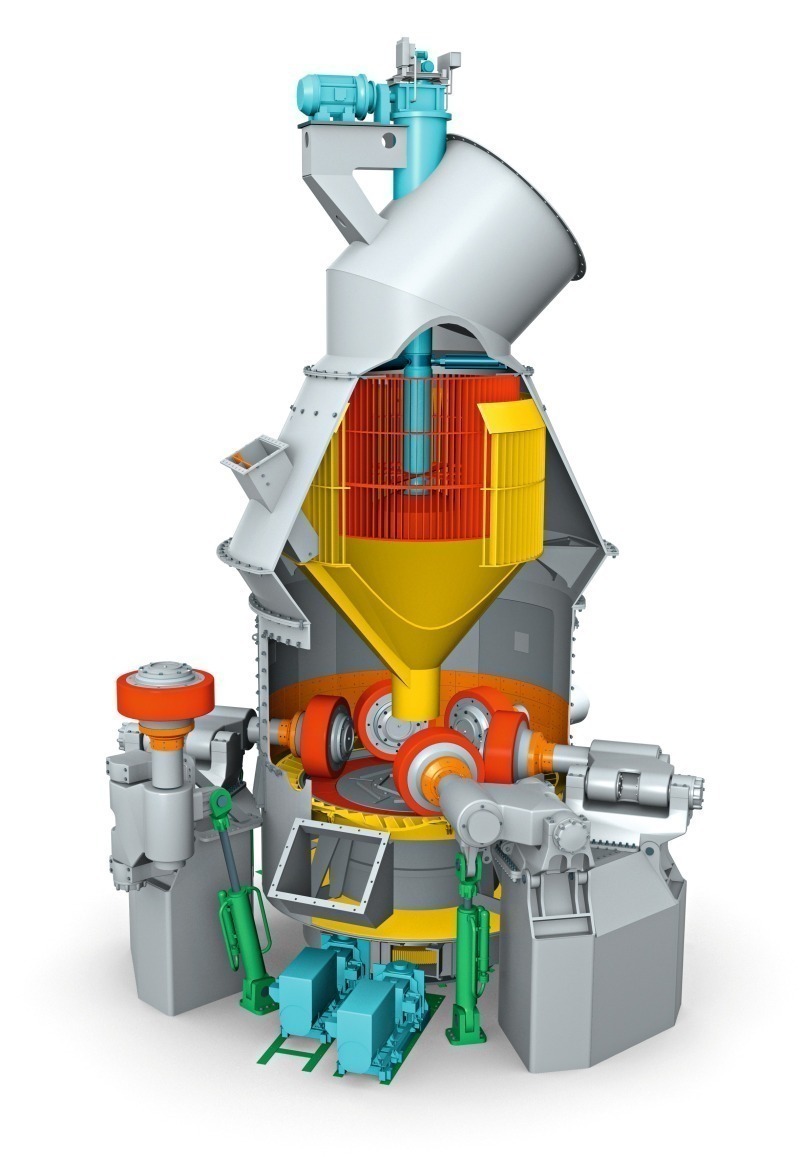

At its core, a vertical roller mill is a highly efficient and versatile piece of machinery designed to grind, pulverize, and classify materials into finer particles. It offers several advantages over traditional ball mills and other grinding equipment.

Progress with Grinding Aids for Vertical Roller Mills

Free Shipping Available. Buy Vertical Roller Mill on ebay. Money Back Guarantee!

Vertical Roller Mill Components & Parts Customizing Service AGICO

A: The grinding process in a vertical roller mill involves drying, grinding, and separation. The material is initially fed into the mill through the inlet chute and then transported to the grinding table. Once the material is on the table, it is ground between the rollers and the table, which generates heat and causes the moisture in the.

Vertical Roller Mill Loesche

OZ Minerals explained in the study: "Vertical roller mills are widely used in the grinding of cement plant feeds and products, slag, coal and other industrial minerals, with thousands currently in operation worldwide. The mill has benefits in reducing power consumption by circa-15%, no ball charge grinding media, higher flotation recovery and.

CLUM Ultrafine Vertical Roller Mill Vertical Roller Grinding Mill Machine

The two most common compressive comminution technologies are the high pressure grinding roller (HPGR) and the vertical-roller-mill (VRM). For now, the HPGR has already presented in a noteworthy number of mining projects whereas VRM technology, a new entrant, is still not fully accepted. This is considered a resistance to change considering that.

Application of Vertical Roller Mill in Cement Production AGICO CEMENT

The vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag. It has the benefits of simple structure and low cost of manufacture and use. Vertical roller mills have many different forms, but they work basically the same.

Vertical Roller Mill for Sale AGICO Cement Plant

The vertical roller mill has the advantages of low energy consumption, high output, easy maintenance, etc., and has been widely applied in cement, steel and power industry, the preparation of non-metallic ore ultrafine powder, manganese ore fine grinding, and other fields. Horizontal Cylinder Roller Mill

Globally established LOESCHE vertical roller mill for use in a cement plant in Pakistan

Contact LOESCHE GROUP EVOLVE THE FUTURE Since 1906 worldwide market leader in designing, manufacturing and servicing vertical roller mills for the cement, power and industrial minerals industries.

Vertical Roller Mills Cement Processing Equipment CITIC HIC

The vertical roller mill (VRM) is heavy mechanical equipment that used in the cement materials industry to process cement, slag, and coal cinder (Pani & Mohanta, Citation 2015). The equipment always needs to work in the environment of heavy load, high temperature, high pressure, high corrosiveness, electromagnetic radiation interference, and multi-field coupling, thus it is easy getting abrasion.

LOESCHE vertical roller mill for SCG Cement in Thailand Loesche

In the study the advantages of vertical roller mill are discussed over ball mills. VRM construction, its process and parameters which affects the performance and productivity of vertical roller mill are discussed. Also the consequences of variations in parameter explained.

Drives for large vertical roller mills Cement Lime Gypsum

quadropol® vertical roller mill thyssenkrupp is one of the few full-range suppliers for the cement industry - from individual machines, all the way up to complete cement plants, and this since decades. The market requirement is easy to define. Present kiln lines have capacities of up to 10,000 tons per day.

Vertical roller mill Hengtu Machinery

VERTICAL ROLLER MILLS played by the mill foundation, which has been optimised to reduce vibrations.2 Built to last The mill foundation, ie, the basic block with its four concrete pylons, is responsible for the smooth running of the mill. The roller units and mill housing are not connected, leaving the mill housing free of forces.

Roller mill GRMK vertical roller mill Xinxiang Great Wall Machinery Co., Ltd vertical

An interesting historical fact is that a vertical roller mill uses the same operating principle as the pistrium or pistrinum, an antique Roman grain mill.The largest grain mills used worked a.

Operating experience with the Pfeiffer MVR vertical roller mill and the MultiDrive® Cement

Vertical milling machine X and Y has digital read out X with power feed Motor 5 HP For more information please contact at :1-226-343-0583. $4,500.00. Mitsui Seiki VR3A. Dunnville. Vertical machining Center XYZ 28" x 17" x 17" 8000rpm spindle cat 40 taper Fanuc 6MB RS232 file transfer tool changer - 20 tools OBO.

Vertical roller millBaichy Machinery

What is a vertical roller mill? A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying.